Streamline Your Process

Maximize Efficiency

Improve Your Bottom Line

Equipment should fit your process,

Not the other way around.

For more than a century, ANCO has been helping customers solve their rendering and processing needs.

How? We understand that no two processes are alike. So, we listen to your specific facility needs,

discover unique solutions, and customize the best solution to fit your process and budget.

Rendering and Processing Equipment

- Raw Material Handling Systems

- Cookers/Dryers/Hydrolyzers

- Separation/Fats & Oils Handling

- Finished Meal Handling Systems

- Chilled Slurry Processing

- Condensing Systems/Odor Control

- Control Automation

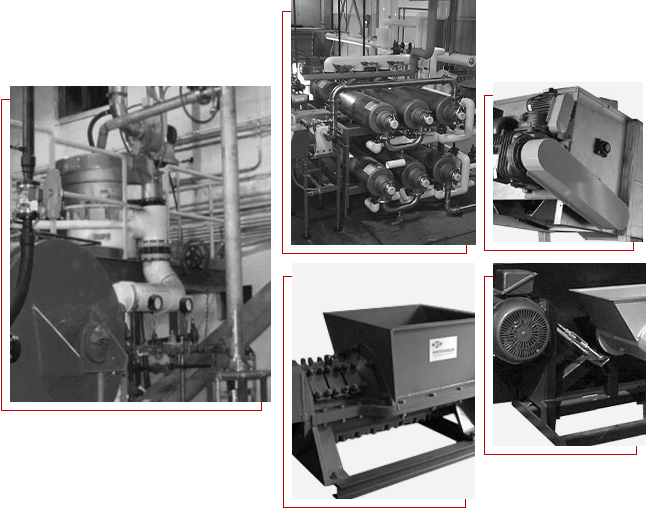

Raw Material Handling Systems

Our Raw Material Handling Systems are cost efficient, durable, and capable of processing whole animals with no preparation required. They are available in a variety of models and sizes that can be customized to your company’s specifications.

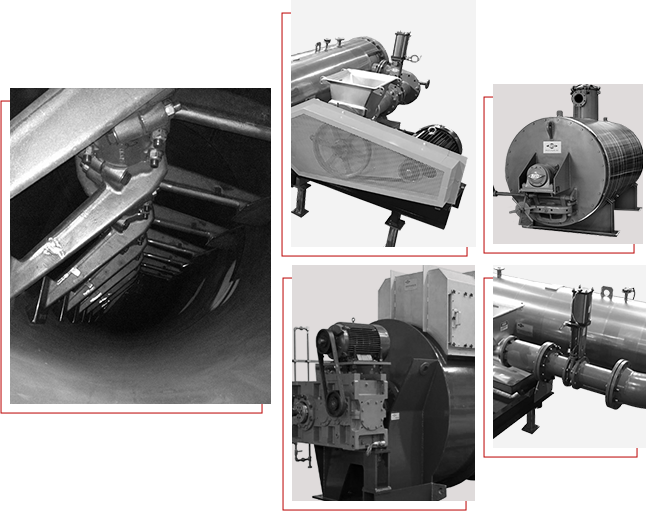

Cookers/Dryers/Hydrolyzers

ANCO Cookers and Hydrolyzers can operate as batch or continuous units for by-products of animal processing.

Separation/Fats & Oils Handling

Materials typically enter the rendering process at 70% moisture. The most efficient way to reduce the moisture content is to mechanically dewater the material with our superior dewatering systems and presses.

Finished Meal Handling Systems

ANCO dryers are well suited for all types of industries and products. Their compact and adaptable design makes it easy and efficient to upgrade from older evaporation.

Chilled Slurry Processing

ANCO manufactures scalable systems allowing you to grind and chill product anywhere from 3,000 to 20,000 lbs/hr and beyond.

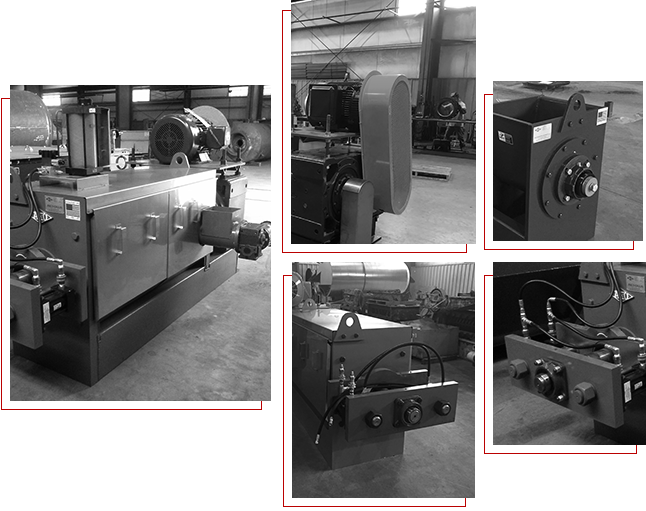

Condensing Systems/Odor Control

ANCO uses a wide range of high quality odor treatment systems for a large range of industries. Our equipment ranges from scrubbers and condensers to cyclones and thermal oxidizers.

Control Automation

ANCO Manufactures scalable systems allowing you to grind and chill product anywhere from 3,000 to 20,000 lbs/hr and beyond.

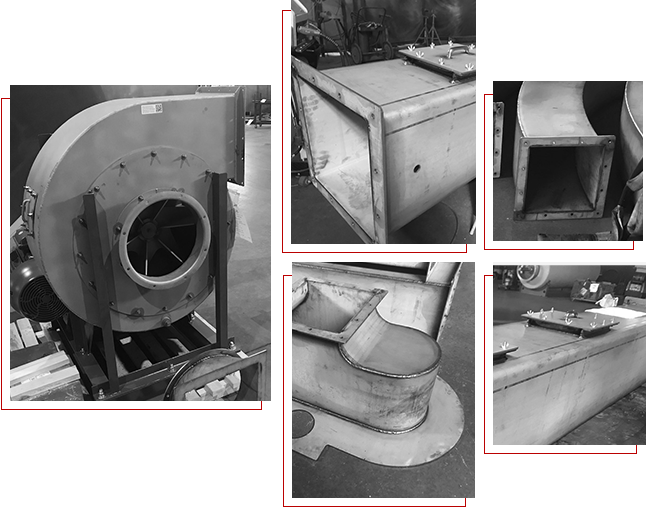

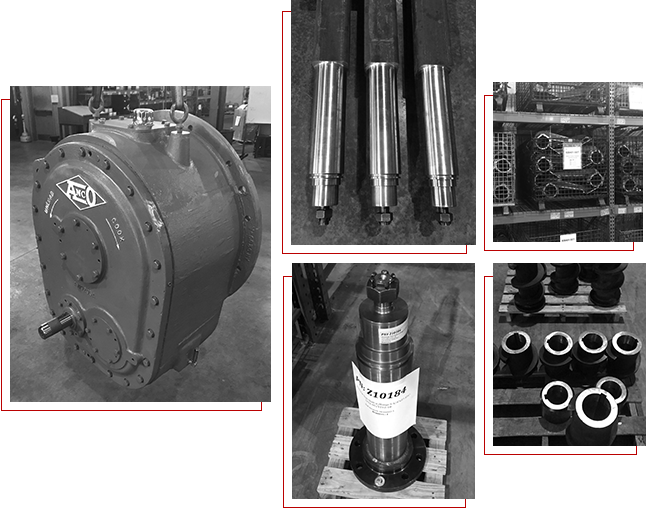

Parts for Rendering &

Processing Equipment

ANCO is committed to maintaining a well-stocked spare parts warehouse. You can count on us to get you the parts you need, when you need them. Our staff of equipment experts will work with you to verify we supply the correct parts for your system. We can also provide installation advice if needed.

We stock parts and raw material to provide fast turnaround of spare parts for all ANCO equipment.

Service

ANCO can provide the service and customer support for all your equipment needs. Our service technicians have the experience and product technology in the following areas.

Rendering Field

Services

- Site Evaluations

- Equipment Installation

- Equipment Maintenance

- Technical Training and Supervision

- Project Maintenance

- Plant and Equipment Appraisals

Repairs and

Maintenance

- Field Repairs

- Cooker Re-shelling

- ASME Code Work

- Ultrasonic Thickness Tests

Engineering

Services

- Custom Equipment Design

- Process Design Including P&ID Drawings

- Site evaluation & Plant layout

- Structural Analysis Including Finite Element Analysis

- Local & International Code Compliance

- Plant Automation Upgrades

- Integration of Equipment & Controls (new and/or existing)

- Energy Consumption Analysis

- Return On Investment (ROI) Analysis

Hear From Some of Our Clients

Generate optimal output and increase revenue with our four-step process:

Get a Custom

Quote

We will assess your plant and discover your unique needs.

Install the Ideal

Equipment

Cost-Effective Processing & Rendering

Watch your rendering process become more streamlined.

Improve Your Facility’s Bottom Line

Increase throughput, reduce downtime, and save money.

We have worked with some of the best companies in the world

Trust the Custom Rendering Solutions Experts

Whether you’re building a new plant or updating an existing line, you want your rendering process running at peak performance to remove waste. To accomplish that, you need reliable rendering equipment and a seamless process that will consistently perform for your size and capacity.

We all know that standard equipment is often more than you need or worse, doesn’t perform reliably once installed. At the end of the day, you end up wasting money trying to keep your process running smoothly. It’s frustrating. We get it.

The bottom line is you should have equipment that fits your plant, not the other way around.

There are plenty of unknowns when you’re adding a line, expanding, or starting a new plant. We understand how critical it is to know your new equipment will seamlessly fit into your process. For more than a century, ANCO has delivered custom rendering solutions for its customers to help them maximize their processing and waste removal, and improve their bottom line.

Don’t struggle with unreliable equipment, poorly designed processes, and unnecessary expenses. Schedule your consultation today and let us help you build an efficient plant that delivers cost savings and generates a return on your investment.

What’s New at ANCO

ANCO is a manufacturer of high quality production machinery in the rendering business, but what most people don’t know is that we also offer a variety of stocked parts.

ANCO Mini Cooker Press Release March 2024

ANCO Unveils the ANCO Mini Cooker: Empowering Small Production Plants with Efficiency and Independence Press Release March 12, 2024 High Point, March 12, 2024 — ANCO, a leader in equipment solutions...

IPPE 2023

ANCO Exhibiting at IPPE 2023 News ANCO EQUIPMENT & SERVICES ATTENDS IPPE 2023 The ANCO Equipment and Services team is excited to announce that we will be attending the International...

The Next Chapter-ANCO

Welcome To The Next Chapter Tom Stanforth speaks out about what is happening at ANCO and how the next chapters are being written for YOU!!